Update (November 11, 2024): All sections of the story have been revised to reflect the latest information. New sections added to the beginning and end of the story.

A battery technology, christened the BYD Blade battery, promised to set a new benchmark in battery safety when the announcement was made in 2020. The BYD Blade battery was planned to be used in select cars, but now BYD has deployed the tech in multiple models and brands, including the BYD Tang EV, BYD Atto 3, BYD Seal, BYD Dolphin, BYD Seagull, and the BYD Sealion 7.

Apple’s reported role

The BYD Blade battery technology was under development for several years, at least since 2017. Bloomberg reported on October 17, 2024, that Apple engineers contributed to this project by sharing their expertise in advanced battery pack design and heat management systems. BYD complemented this collaboration with its own manufacturing prowess and advancements in lithium iron phosphate (LFP) cell technology. It’s noteworthy that Apple doesn’t own any of the technology which we see in BYD’s models.

Advantages of the BYD Blade battery

The Blade battery comes with a lithium-ion phosphate (LFP) chemistry as opposed to the usual nickel manganese cobalt (NMC) mix. Instead of having multiple modules, the BYD Blade Battery stacks all the cells together, saving over 50% space compared to other battery blocks.

According to He Long, Vice President of BYD and Chairman of FinDreams Battery Co, the Blade batteries have four advantages:

- slow heat release

- low heat generation

- high starting temperature for exothermic reactions

- ability to not release oxygen during a breakdown

BYD was one of the first companies to use a battery thermal management system (BMS) to ensure that the temperature of the batteries remains at the optimum level in all extreme weather conditions. The energy efficiency of BYD Blade batteries is so high that it allows the company to produce NEVs with some of the industry’s longest ranges. The company’s efforts in the development of battery technology over the last 27 years have truly paid off.

No smoke or fire after nail penetration

BYD says its LFP technology is at the heart of its new energy vehicle (NEV) line-up. The largest manufacturer of LFP batteries expects them to account for more than 60% of the global power battery market by 2024. The cobalt-free batteries, produced using a material possessing greater thermal stability than other battery alternatives, have passed stringent safety tests, including overcharging tests, crush tests, and heat tests.

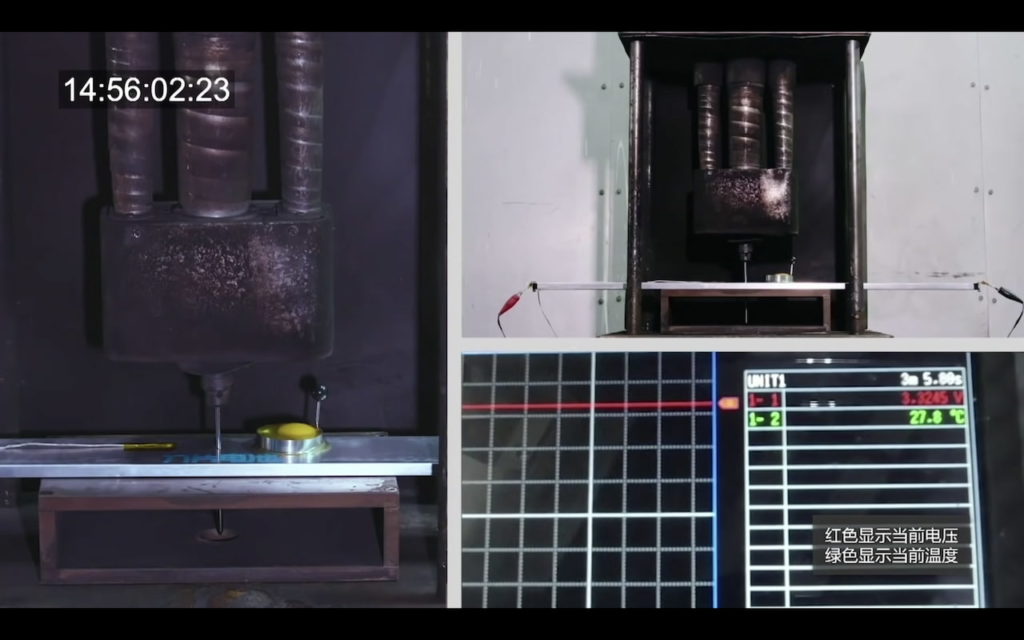

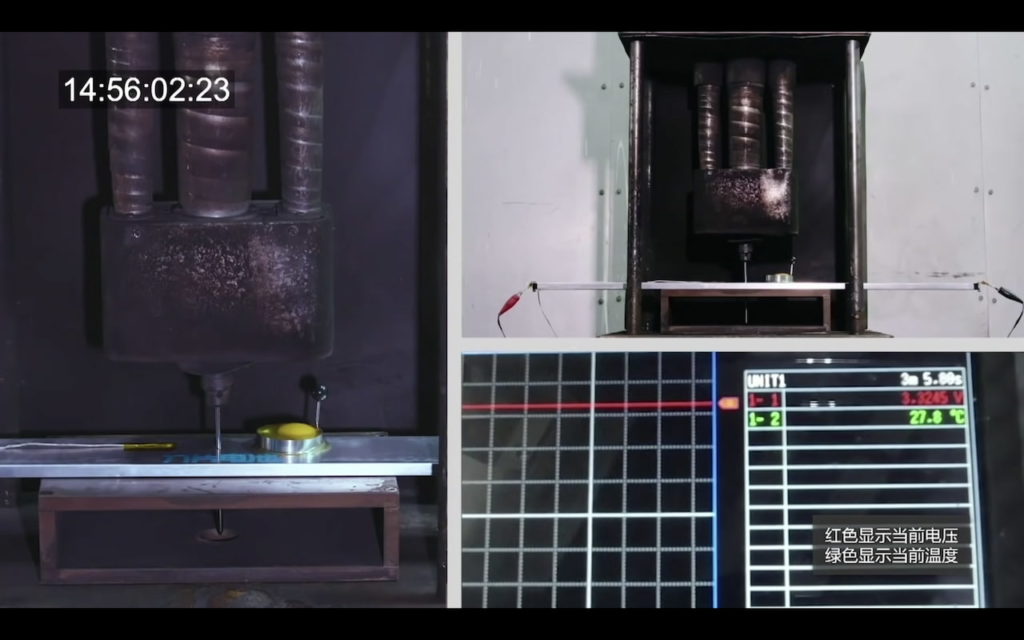

Conditions of the nail penetration test

BYD’s engineers subjected the battery to nail penetration, heating to 572º Fahrenheit, overcharging to 260%, and structural rigidity tests. The battery did not emit smoke or fire during nail penetration, and the surface temperature ranged between 30-60 degrees. In the same tests, a ternary lithium battery went past 500º C and burned, and a conventional LFP block battery reached a temperature of 200º to 400º C but didn’t emit fire or smoke.

Three types of batteries were put through the nail penetration test in the lab. Firstly, an NMC battery was subjected to this test with an egg placed on its top. The NMC battery exploded instantly when the nail went through. In the second test, a regular LFP battery was penetrated, again with a raw egg placed on top to check overheating. As the test proceeded, the egg was burned, and temperatures of up to 400º were recorded. And lastly, when the nail penetrated the BYD Blade battery, the egg remained uncooked, indicating no heating problems.

Furnace & Structure tests

That’s not it. BYD put the Blade battery into a 300º C furnace from which the unit emerged unscathed. Even after overcharging it to 260%, no fire or explosion was reported. BYD performed an extreme structure test where a 46-tonne truck drove over the Blade battery, but that didn’t cause leakage, deformation, or smoke. BYD said that the battery was perfectly intact after the test and still usable in an EV.

Specifications

The BYD Blade battery uses a single-cell design which is compact. The single cells are positioned in an array and inserted in a blade-type arrangement into a pack. It promises a life of over 1.2 million km after 3,000 charging/discharging cycles. This arrangement allows a life span of over 740,000 miles (1.2 million km) after 3,000 charge/discharge cycles.

| Aspect | BYD Blade battery cell specification |

| Chemistry | LiFePO4 (LFP) |

| Capacity | 202 Ah |

| Nominal Voltage | 3.2 V |

| Maximum Charging Voltage | 3.65 V |

| Energy Content | 646.4 Wh |

| Length | 905 mm |

| Width | 118 mm |

| Height | 13.5 mm |

| Volume | 1.4 L |

| Volumetric Energy Density | 448 Wh/L |

| Weight | 3.9 kg (est.) |

| Gravimetric Energy Density | 166 Wh/kg |

| Cycle Life | 3,000+ cycles |

Other manufacturers have also adopted the BYD Blade battery. Toyota has adopted the Warren-Buffett-backed brand’s technology, using it in the Toyota bZ3 sedan. KG Mobility (formerly Ssangyong Motor) is also expected to use Blade technology widely in future models.

Second-generation BYD Blade battery

Reports have emerged that the Chinese automaker is developing a second-generation Blade battery. The reported energy density varies between 180 Wh/kg to 190 Wh/kg, which is at least 20% better over the current energy density of 150 Wh/kg. Mated to a fifth-generation chip, the new battery would reduce power consumption by 20% and increase the driving range by 3%, earlier reports said.

The Yangwang U7 sedan will feature the second-generation Blade battery, capable of a charging rate exceeding 5.5 C and a discharging rate over 14 C, according to Wu Ying, editor-in-chief of the local automotive media outlet Xchuxing, in a Weibo post, on October 30, 2024. 5.5 C connotes that the battery can be fully charged (theoretically) in about 11 minutes.

Overall improvements

Chinese portal MyDrivers reported on April 8, 2024, that BYD Chairman Wang Chuanfu has said that the second-generation Blade Battery features a smaller, lighter battery pack and lower power consumption per 100 km (62 miles) for the same range. This means that the battery not only has an improved energy density but also an optimized size, weight, and efficiency, enhancing the range and overall performance (power and torque) of the EV in which it is deployed.

With the same range, the new generation of Blade Batteries is expected to be more compact and lightweight, leading to a lower production cost for the battery pack. This smaller design not only generates spacious cabin, addressing the space limitations common in city electric models, but also helps BYD reduce costs, giving it a competitive edge.

Featured Image Source: BYD

I’m an automotive journalist with 4 years of experience in magazine and digital publishing, content creation, social media management and YouTube. A car enthusiast who converted my passion into a profession!

Comments are closed